Kolchar Product Line

Kolchar-GF series

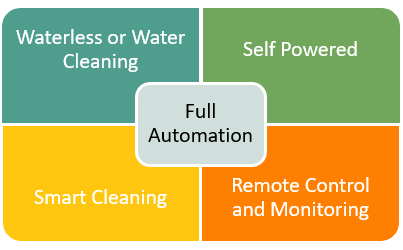

The Kolchar-GF series are designed and optimized for ground-fixed solar power plants. Kolchar-GF features water-free cleaning, self-powered, remote control and monitoring, data management, smart weather-aware operations, and so on.

Different solar power plant operators may have varying O&M requirements, primarily influenced by differences in power station layout and implementation. The Kolchar-GF robot is specifically designed to meet the needs of most ground-fixed installations across various solar power plants. Its versatility allows for flexible customization to accommodate the specific requirements of individual customers.

Kolchar-TR series

The Kolchar TR features autonomous and smart operation, superior capability to handle misalignments, long endurance, easy maintenance, reliability, multiple safety measures, and compatible with mainstream trackers from different manufacturers.

With our engineering and design expertise, the Kolchar TR robots can reliably handle:

- Height difference between two trackers: ±50mm

- Angular difference between two trackers: ±5°

- Horizontal misalignment: ±50mm

- Obstacles such as BHAs, slew gear, and antenna

- Gaps between two adjacent panels or two trackers (with the help of dynamic bridges)

Newly launched Kolchar-SP series

The Kolchar SP series of portable PV panel cleaning robots offers unparalleled flexibility for adapting to various solar site layouts and configurations, providing efficient and effective PV panel cleaning. This series consists of two models:

Kolchar SPI:

- Lightweight and Portable: Each robot weighs just 6.2 kg, allowing easy transport to hard-to-reach areas.

- Versatile Capabilities: Operates at inclination angles up to 45 degrees and in temperatures ranging from -20°C to 50°C, including nighttime operations.

- Autonomous Operation: Independently navigates and cleans solar tables after a simple start button press, enabling one staff member to operate multiple robots simultaneously.

- Universal Application: Suitable for all types of terrains, plant layouts, and panel configurations, including rooftops, tracker projects, and areas where dust needs to be vacuumed instead of brushed away.

Kolchar SPE

- Enhanced Cleaning Efficiency: Delivers high cleaning speed and efficiency, capable of covering up to 1,000 m² per hour.

- Dual Cleaning Modes: Supports both dry and wet cleaning, with options for pressure washing PV panels or using specialized solutions to remove stubborn pollutants.

- User-Friendly Operation: Features remote control with auto-cruising, anti-slip, and fall-prevention mechanisms. AI-based autonomous path correction ensures stability, safety, and ease of use.

- Modular Design: Facilitates quick assembly of brushes, water sprayers, and other components for easy portability and maintenance.

- Versatile Application: Suitable for cleaning panels with inclination angles up to 25° and in temperatures from -10°C to 45°C.

System Advantage

Field Tests and Certifications

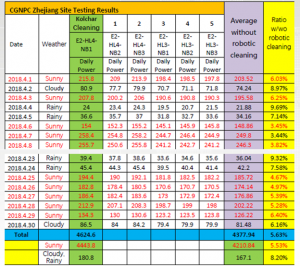

Field Tests

A field test was conducted at one of the solar power plants operated by China General Nuclear Power Group (CGN) to evaluate the efficacy of our robotic PV panel cleaning solution. The test focused on daily panel cleaning using our robot.

The results showed an improvement in power generation of approximately 5% in the soiling condition at the CGN solar power plant.

TUV certification

The robot demonstrated consistent and effective cleaning performance. Simulated 25 years of operations revealed no defects on PV modules.

Power degradation was only 0.249%, and no new microcracks were found on PV modules after testing.